VibroTrace System Setup

Compact hardware with clear interfaces ready for production environments.

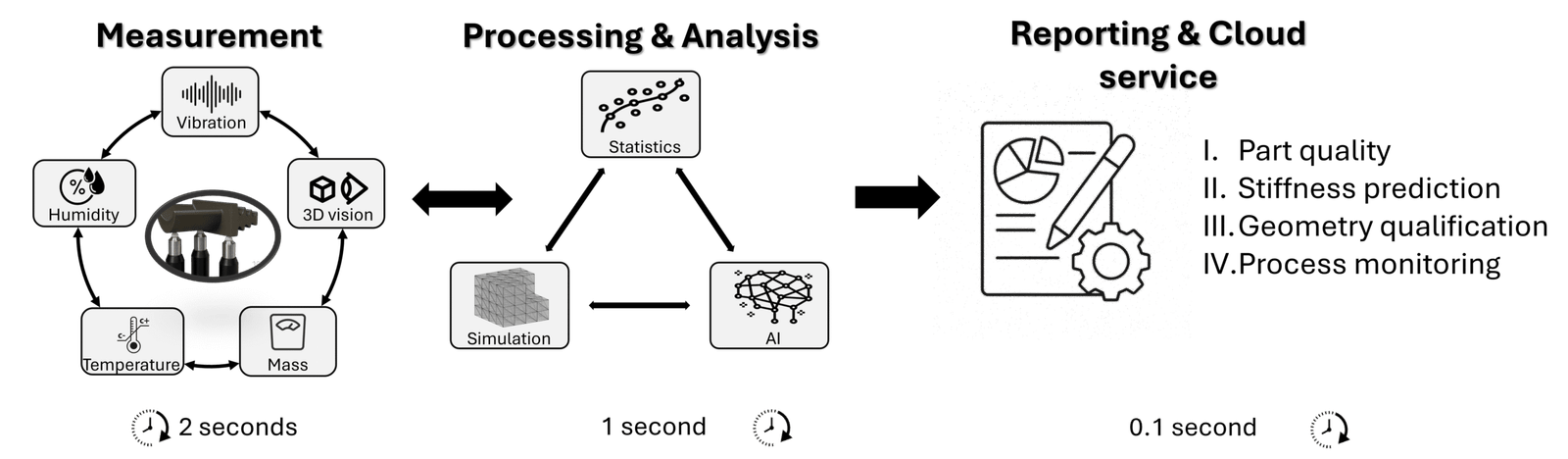

Our Technology

VibroTrace offers automated and reliable quality control of your manufactured parts within seconds. The strength of our technology lies in the multi-facetted measurement approach integrated with model-driven artificial intelligence, and cloud-based reporting. The operator simply puts the part on our specialized fixture, and our technology does the rest.

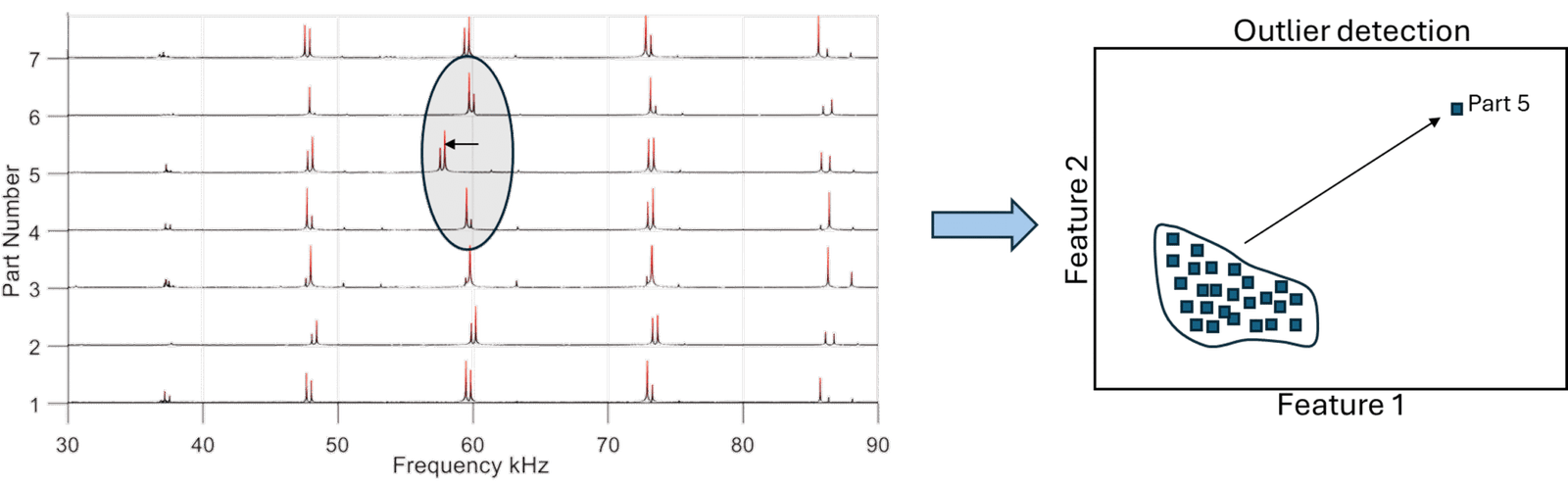

Resonant Testing

VibroTrace vibrational testing acquires a complex resonant spectrum which can be seen as a fingerprint of the part quality. Any deviations in this fingerprint might indicate quality issues such as cracks, porosity and even residual stresses. Our advanced statistical tools interpret the fingerprint and highlight possible low-quality parts as outliers.

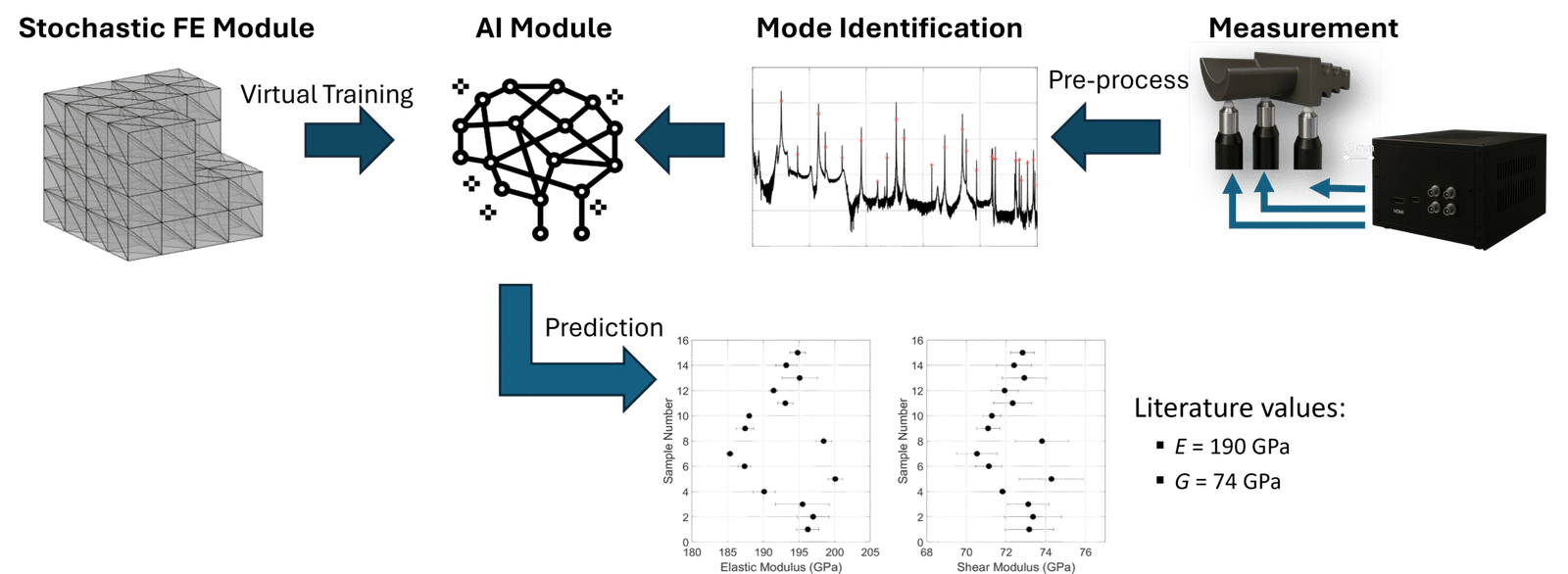

Mechanical Stiffness Prediction

VibroTrace offers a virtually trained machine-learning model that provides an instantaneous prediction of the stiffness of your part, such as Young’s modulus (E) and shear modulus (G). This offers a fast and cost-effective alternative to classical destructive tensile testing.

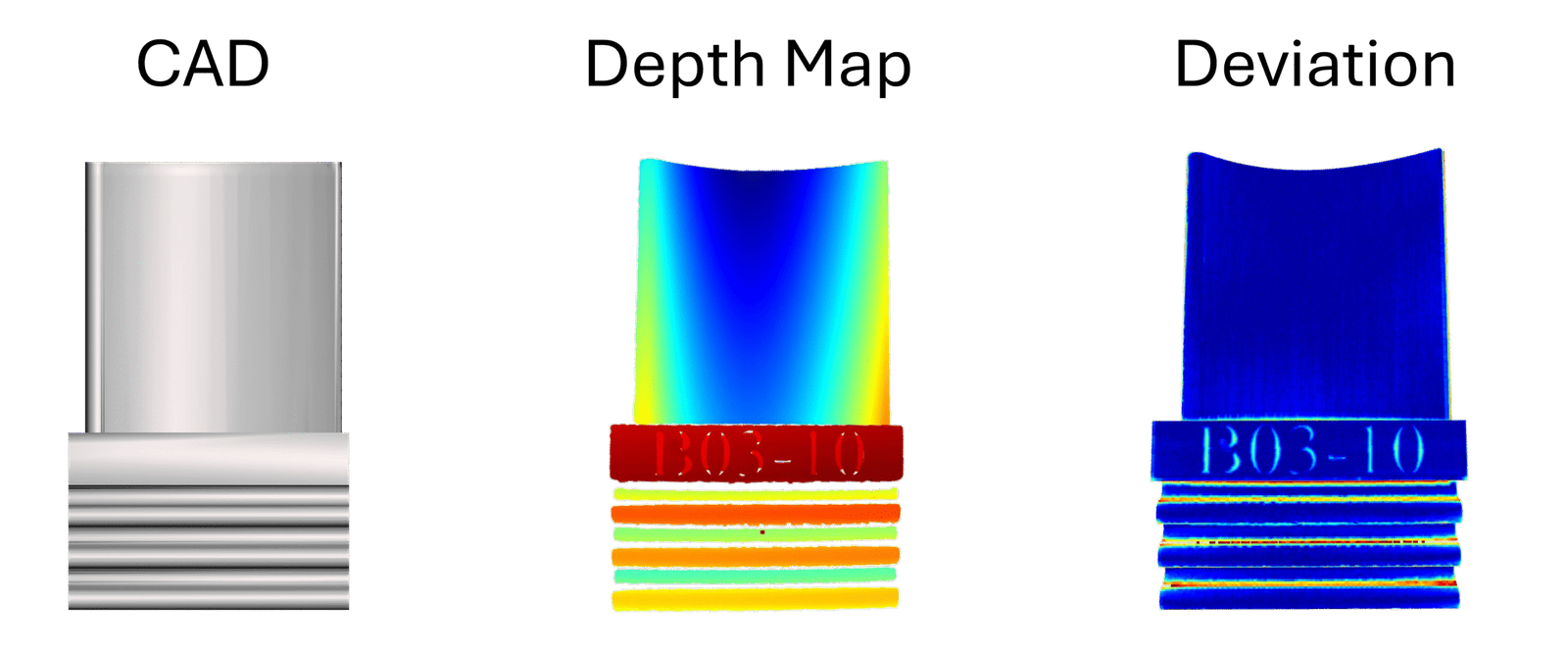

Geometry Qualification

VibroTrace uses a 3D laser snapshot sensor to acquire geometrical data for any part, regardless of surface quality or lighting conditions. With micrometer-level height resolution, it verifies even the smallest tolerances. A matching procedure projects the measured geometry onto the nominal CAD model to visualize deviations directly. For high-volume serial production, automated label reading enables efficient, error-free campaigns.

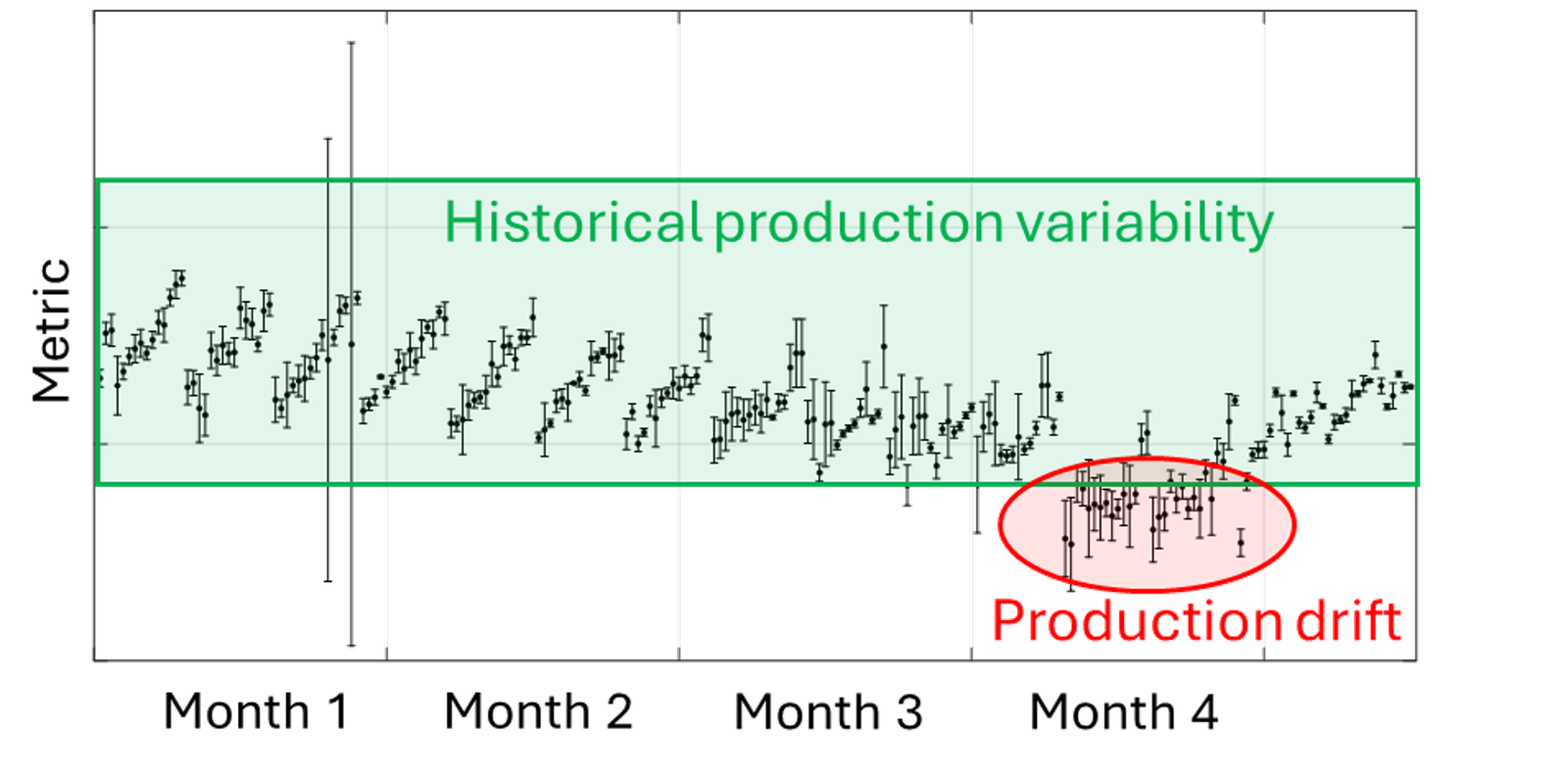

Long-Term Process Monitoring

VibroTrace also monitors environmental conditions, such as temperature and humidity, resulting in highly reliable and stable measurements over time. This enables insight into long-term production variability and early identification of drifting processes.